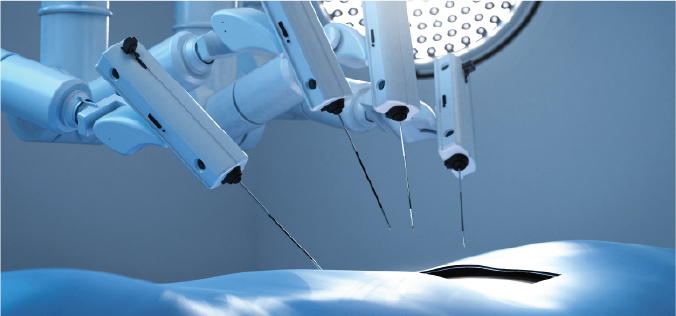

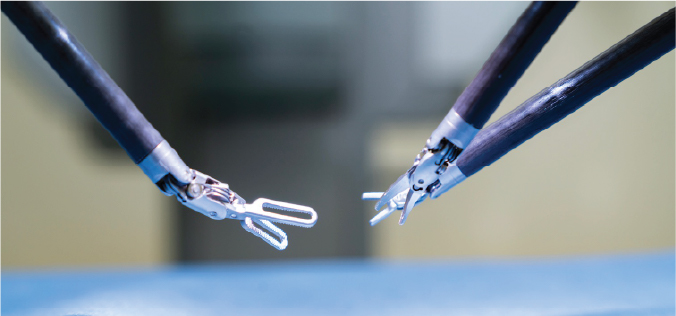

Applications

A range of materials and services that apply to minimally invasive procedures

Through small incisions and natural openings in the body, minimally invasive procedures achieve diagnostic and therapeutic goals without traditional “open” surgery. As a result, they generally create less tissue trauma and infection risk, which benefits both patient and clinician.